Titanium supply: the benefits of turning to/working with a stockist

Hemocompatible, titanium is a material of choice for cardiac implants, such as FineHeart's Icoms Flowmaker. The start-up has chosen to buy from Acnis International, which can deliver semi-finished products in titanium, but also in Co-Cr, stainless steel and PEEK, in less than a week.

Established in Lyon, the stockist Acnis International is one of the world leaders in the distribution of metal alloys in all forms: sheets, bars, tubes and powder for 3D printing. ISO 13485 certified, among other things, the family business has specialized in the medical field since its creation in 1991, to meet the demand of orthopaedic manufacturers and dental implants, as well as surgical instruments. As Franck Picard, Acnis’ sales director explains, "although these manufacturers can go directly to the producers of titanium and other technical alloys, they often face high minimum of quantities and delivery times that can reach several months. The problem is particularly tricky for small companies that do not need large volumes.”

Acnis International acts as a buffer between producers and users, thanks to its 600 to 700 tons rotating stock and 1,300 references of different origins. As a result, the company is able to deliver very quickly its customers, in barely a week, no matter the ordered quantity. Major implant manufacturers among the main American and European OEMs themselves call on Acnis International to source their metal alloys.

For now, a limited quantity titanium need

Acnis International's offer is of great interest to start-ups. For instance, this is the case of the FineHeart implant manufacturer. Based in Cestas (33), the company is working on an innovative heart pump: the Icoms Flowmaker. We have had the opportunity to talk about it in the previous DeviceMed magazines (page 36 of the July/August 2019 and page 26 of the March/April 2021). The French company is still in the early stages of development, with limited production of approximately ten devices per month for animal testing needs.

The pump parts, mostly cylindrical, are mainly in titanium. "To supply ourselves, we initially called on another stockist, with whom we had a few disappointments," explains Julien Cardon, production manager at FineHeart. "After testing Acnis, we were able to appreciate its reactivity, an essential quality for us. Today, the company supplies FineHeart with TA6V titanium bars.”

Icoms Flowmaker: a promising alternative to LVAD

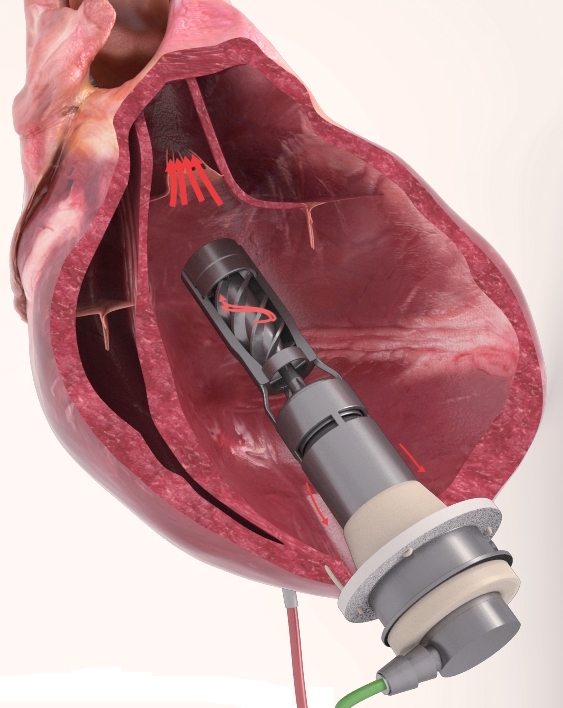

FineHeart's Icoms Flowmaker is a unique intraventricular heart pump. Only 10 cm long, the device provides physiological support synchronised with the natural heart contractions. It has no external power supply as it is recharged by a transcutaneous energy transfer (TET) system.

FineHeart has demonstrated that its pump implantation (minimally invasive beating heart) and removal protocol solves the severe complications associated with conventional left ventricular assist device (LVAD) implantation, which deteriorate the fragile cardiovascular status of treated patients.

In order to move to the pre-industrialisation stage of its device, the company has just raised €15 million. The Basque aeronautics group Lauak is involved in this financing, and is keen to diversify by participating in the industrialisation of the Icoms Flowmaker.

Implementation in humans is planned for 2022.

Regarding titanium machining, FineHeart has a 5-axis HSM workshop and a lathe, both from DMG Mori brand, which are sufficient for its needs, at least for the time being.

PEEK parts also available

Some parts of the Icoms Flowmaker are made of PEEK to prevent endothelization (tissue regeneration), which can impede the flow of blood through the pump's intake and propulsion ports.

Acnis International also offers PEEK, with Evonik's Vestakeep range, for which the stockist has become the exclusive distributor for France, Spain and Portugal (see page 50 of the January/February 2021). Samples have been supplied to FineHeart and are currently under evaluation.

A titanium market weakened by the health crisis

Titanium remains Acnis International's flagship material, serving the medical devices market as well as the aerospace and industrial markets (oil, food, nuclear, etc.).

Franck Picard reminds us that worldwide, titanium production amounts to 150,000 tons per year, from which nearly 5,000 tons are for the medical sector, far behind aeronautics, which remains the largest consumer despite the health crisis. This situation has affected the distributor, but to a relatively small extent, since the aeronautics sector's share was limited to 20% of its activity before the crisis (now down to 13%), while the medical sector's share is over 60%. However, as Franck Picard points out, "the medical activity drop (of around 10%) actually corresponds to a time lag because it’s essentially due to surgical operations postponements".

When asked about the future of cobalt-chromium in medical implants, Franck Picard says that his company has not felt any drop in demand. It should be remembered that as cobalt is now classified as a CMR substance (Carcinogenic, Mutagenic or toxic for Reproduction), the use of cobalt-chromium alloy is likely to be banned according to the new regulation on medical devices (2017/745), unless there is no alternative to its use. "There are lots of questions about who makes decisions on this matter in the European community, the US and elsewhere," Franck Picard underlines, "and how we could put forward our expertise on the subject. A word to the wise...

In any case, "there is no real 'effective' replacement solution for the moment, except perhaps titanium," he concludes.

Twitter

Twitter LinkedIn

LinkedIn